RESEARCH

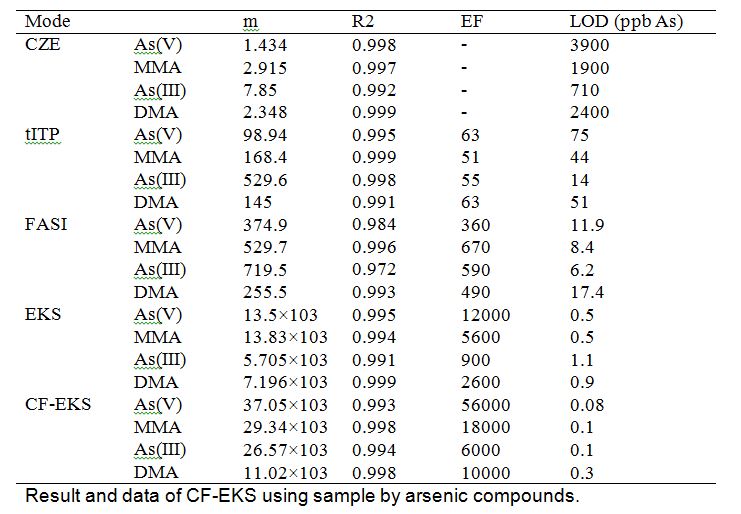

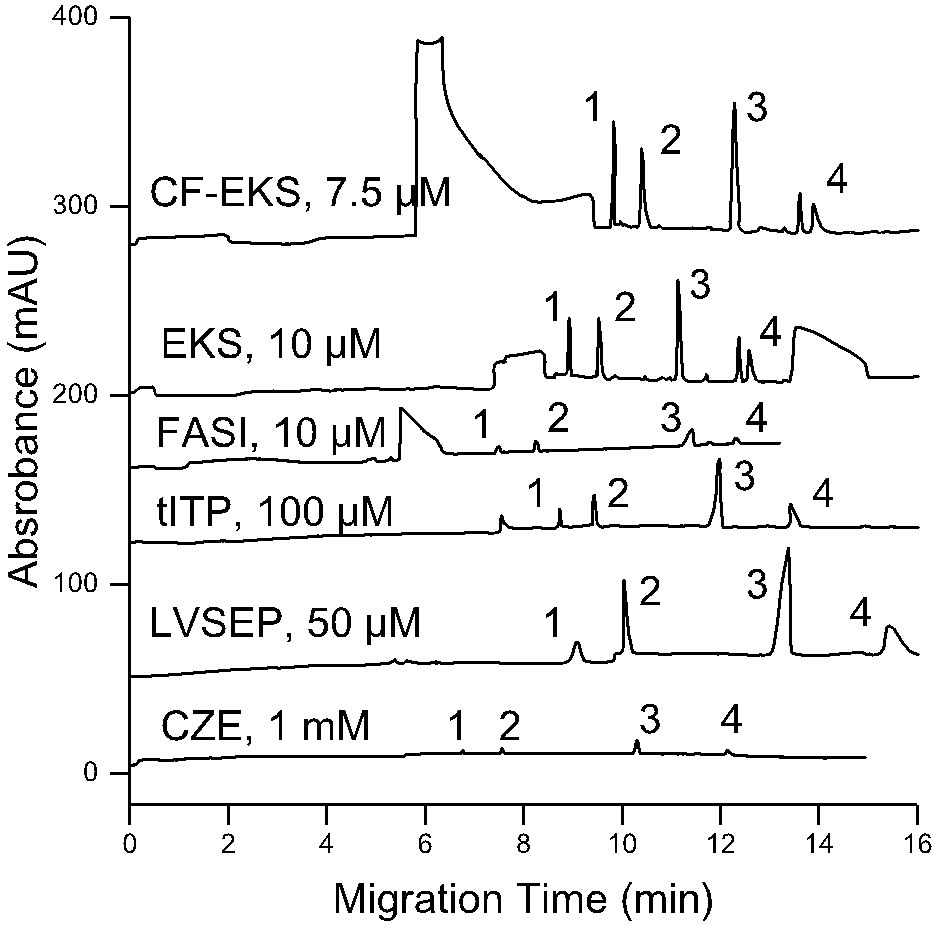

Capillary electrophoresis (CE) provides high performance separation but suffers from the low sensitivity for widely used absorbance detection due to the short optical pathlength of a capillary. Because of this, many stacking and extraction technique has been developed. Counter-flow (CF) electrokinetic supercharging (EKS) is one of the technique to enhance the detection sensitivity. This method provides easy and efficient analyzing method without additional detecting devices.

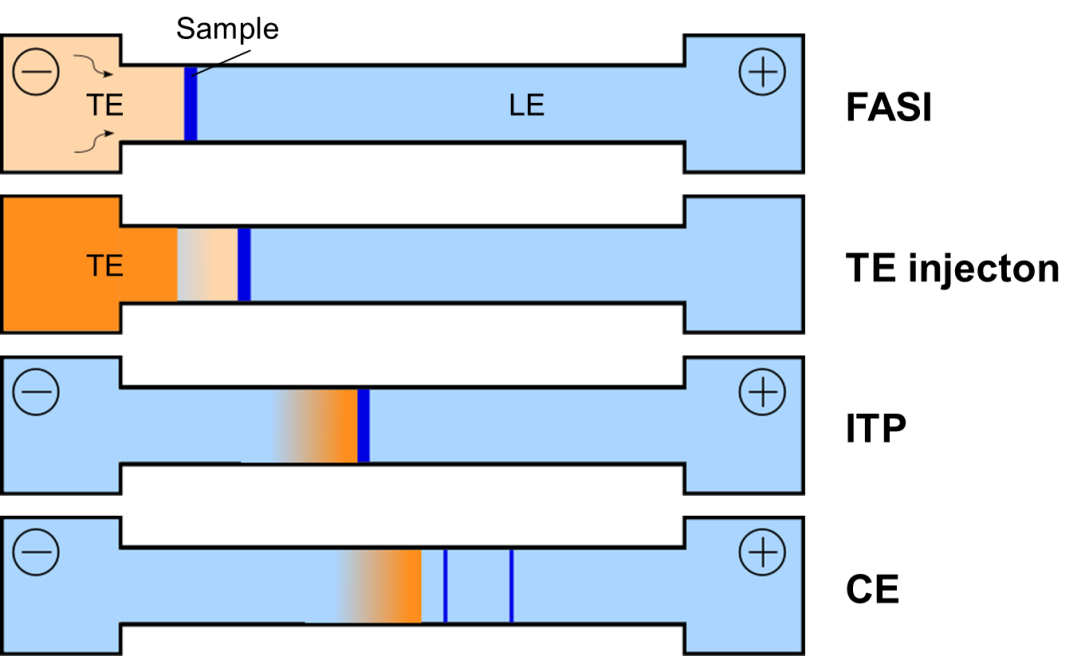

CF-EKS is a method which combines some different sample concentration methods. Electrokinetic supercharging (EKS) is combined with field amplified sample injection (FASI) and transient isotachophoresis (tITP), and CF-EKS is adding counter flow at EKS that help to inject and separation.

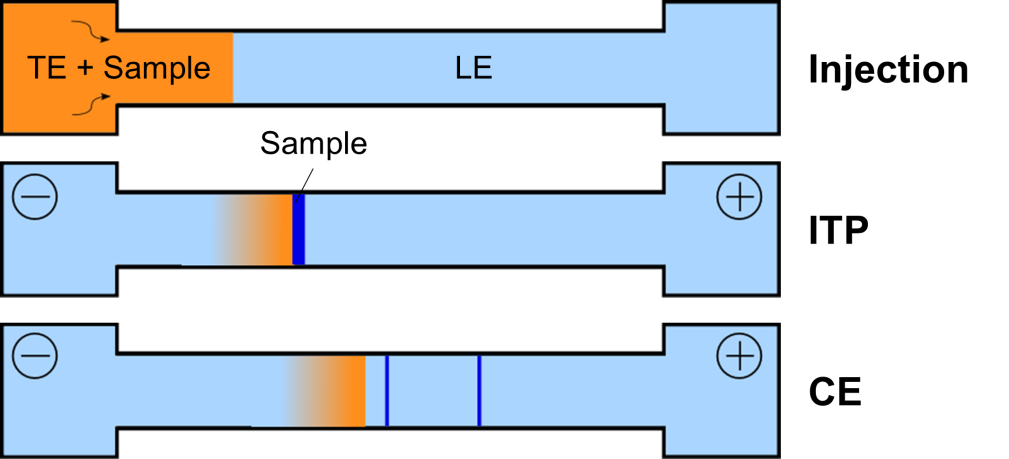

TITP is one of sample stacking techniques using difference of ion mobilites, which binds isotachophoresis with zone electrophoresis (CZE). ITP is just stacking technique, not separate. For separate this, use LE after TE that makes continuously CZE. Leading electrolyte (LE) has high mobility. In contrast, terminating electrolyte (TE) has low mobility. As a result, there become difference of mobility, sample is compressed between LE and TE. Sample stacking will continue until LE passing through TE. Then samples are separated.

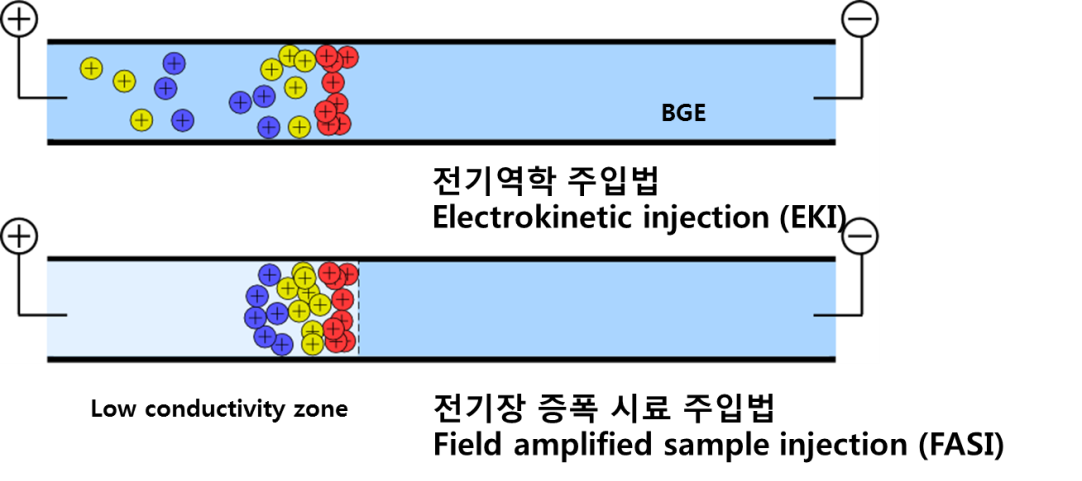

FASI uses electric field difference caused by conductivity difference. After filling the whole capillary with run buffer and low conductivity sample with electrokinetic injection (EKI). Sample stacked at the boundary of sample and run buffer because of high electric field occurred at the injection point.

EKS is improved sample stacking technique using FASI with tITP. LE has high conductivity but TE and sample zone has low conductivity. That makes high electric field in electrolyte boundary. And this difference makes sample stacked in electrolyte boundary.

One limitation of EKS is that the portion of the capillary length filled by FASI should not go beyond the point of allowing acceptable separation for the subsequent tITP.

Counter Flow Electrokinetic Supercharging (CF-EKS) is simple improvement of EKS.

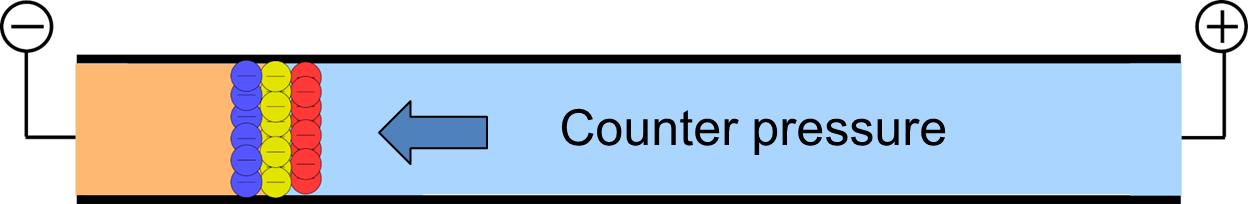

CF-EKS uses a counter pressure to counterbalance the movement of the stacked sample zone during injection. This counter flow makes stop the electrolyte boundary near inlet of capillary. By this, we can inject much more and sufficient separation length

CF-EKS strong point is no need to sample preparation step, not much effected by sample ionic strength, provides easy and efficient analyzing method without any additional device. And it has low cost and high sensitivity. And more, it can be applicability to various samples.

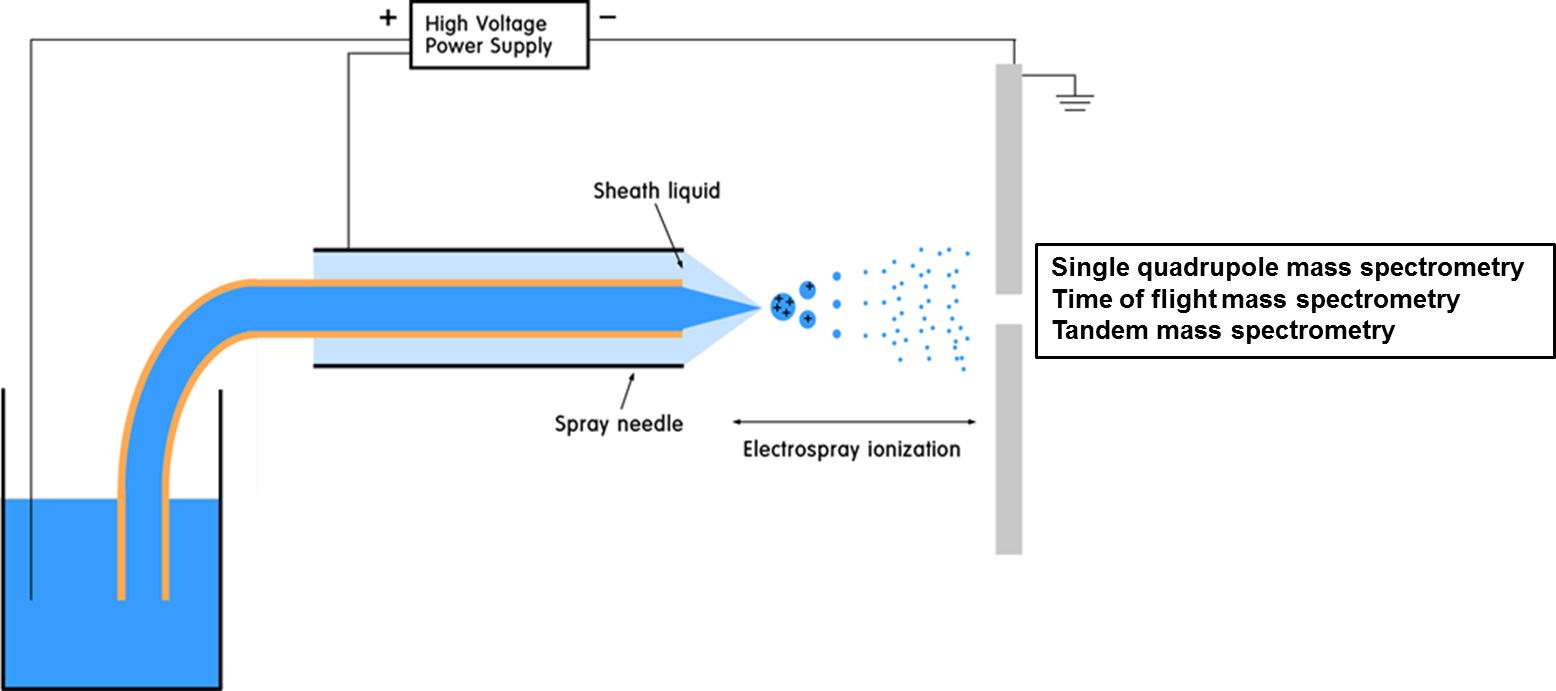

Capillary electrophoresis mass spectrometry

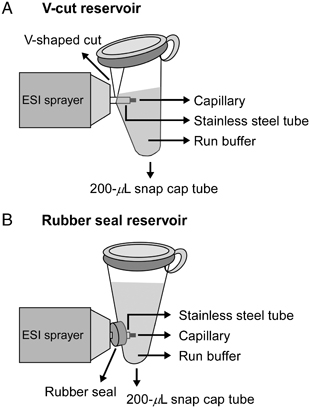

Fig 1. Simple schematic for CE-MS

Fig 2. ESI at the end of the tip

Fig 3. ESI tip modification

Capillary electrophoresis mass spectrometry (CE-MS) is the most powerful method for sample analysis (Fig. 1). Not only it improves the sensitivity, but also provides qualitative results by mass spectra and tandem mass result. We uses homemade electrospray ionization (ESI) for connecting capillary electrophoresis to mass spectrometry (Fig. 2). Our lab��s goal for improving CE-MS is adding inline capillary electrophoresis extraction/stacking methods. This will help to use small amount of samples and give more chances for accurate analysis. We uses modified ESI sprayer, which enables to apply flow control stacking methods such as SDME and LVSEP (Fig. 3). We are currently working on more reliable methods to improve current modifications

Related publications

Large Volume Stacking Using an Electroosmotic Flow Pump in Nonaqueous Capillary Electrophoresis-Mass Spectrometry Jihye Kim, Man-Seog Chun, Kihwan Choi, and Doo Soo Chung Electrophoresis 30, 1046 (2009)

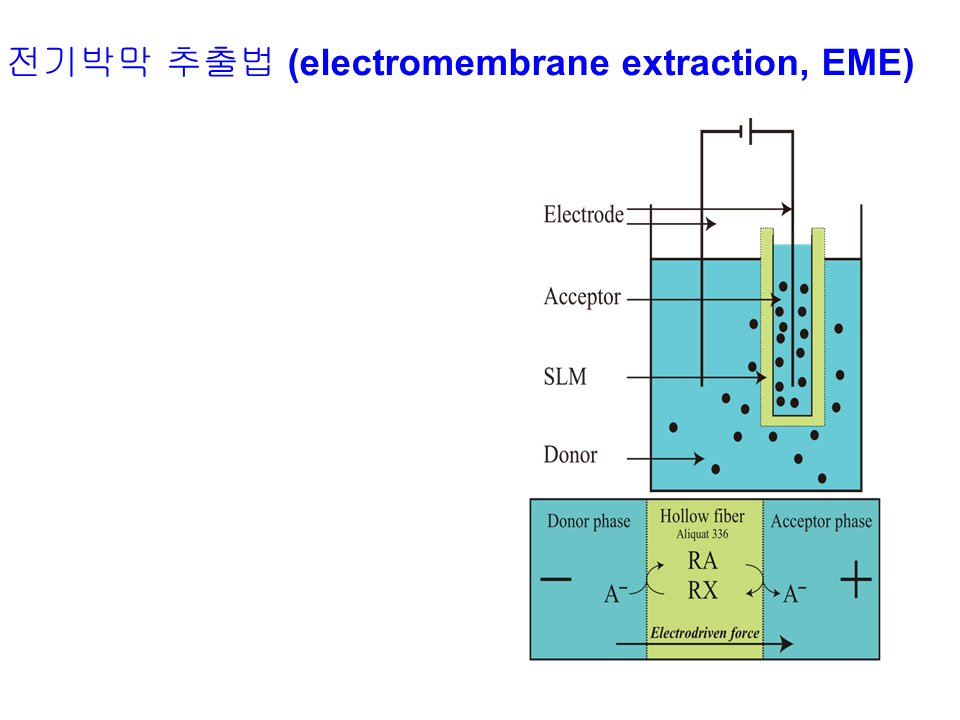

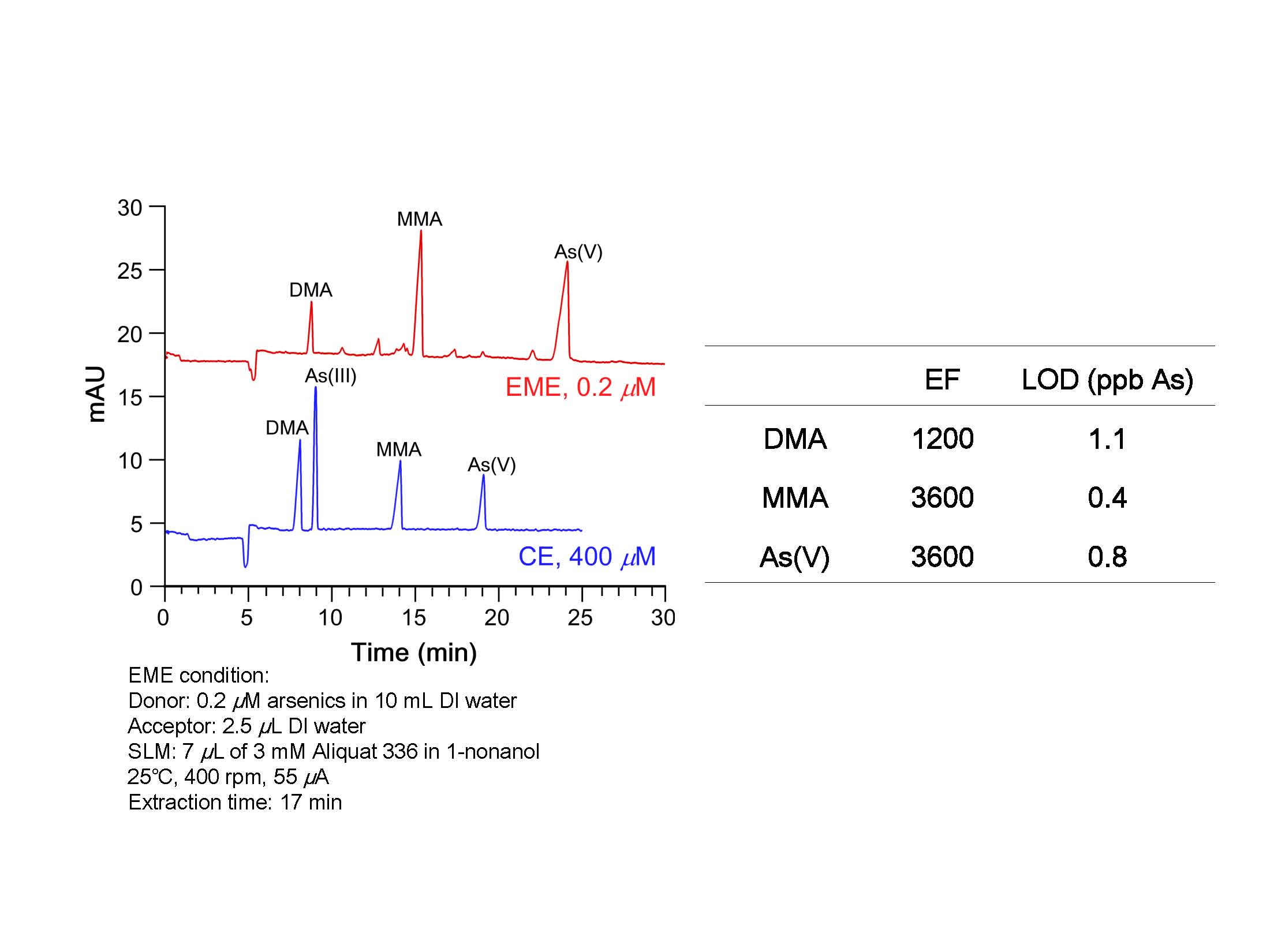

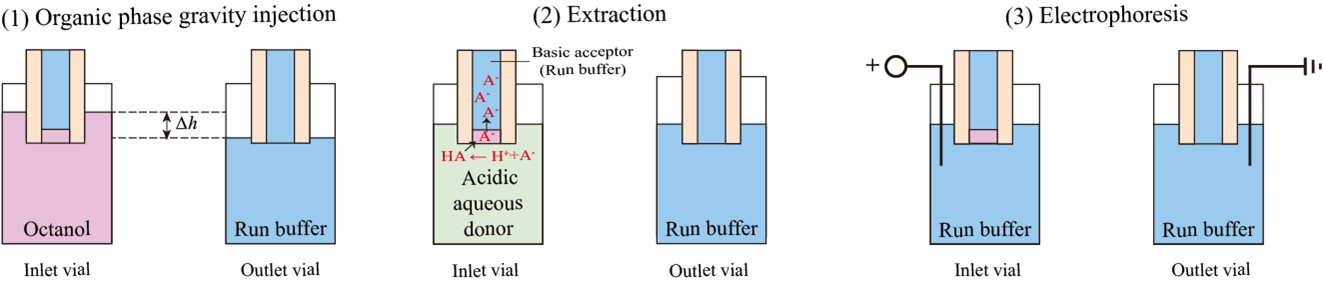

Membrane

3 Phase DI-ITME

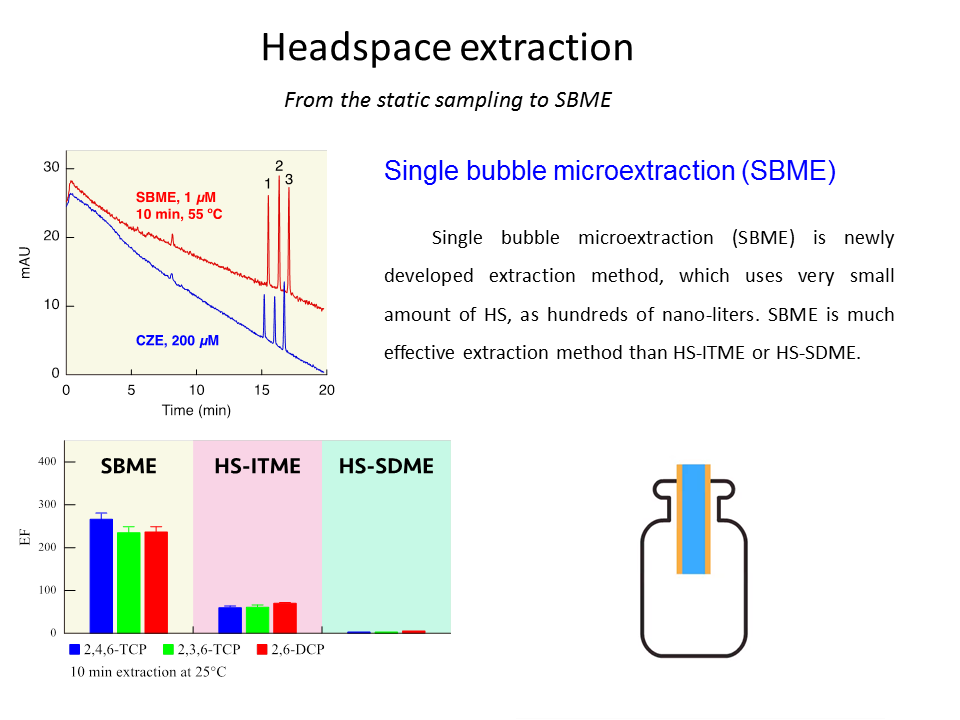

Headspcae extraction

Lab-on a chip by 3D printer

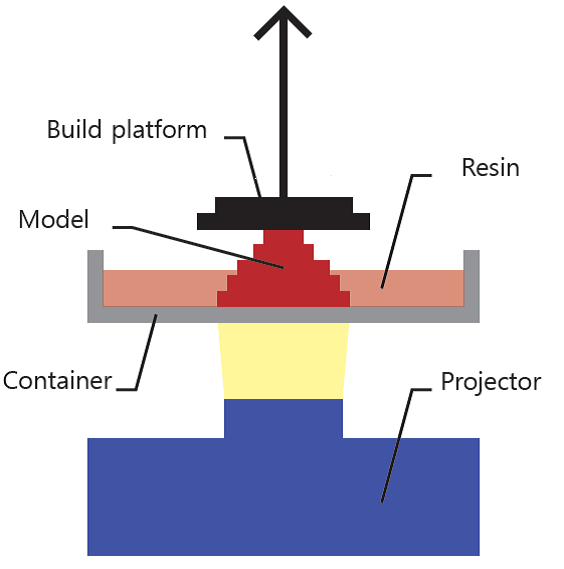

3D printer (DLP based)

<3D printer 'Titan 1' by kudo3D (DLP based)>

I'm making micro-device for analysis by 3D printer. The 3D printer is based on digital light processing(DLP).

Digital Light processing (DLP)

DLP is a method using photocurable resin. When you lay light to the container by projector, the resin is polymerized on the build platform. After this procedure is repeated, the model you want to make is done.

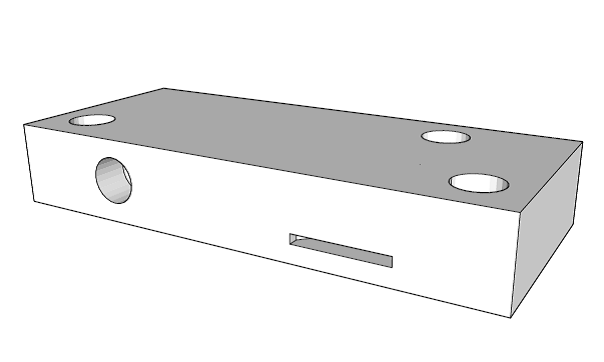

Micro-device model

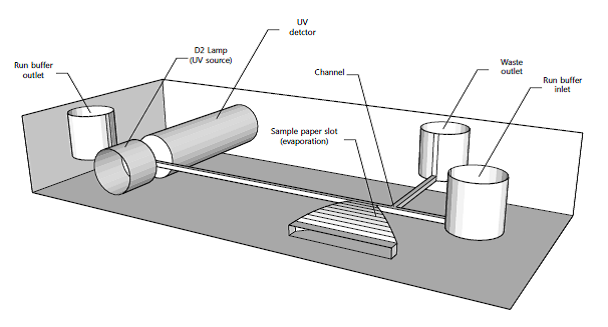

This is the micro-device I want to make. First, fill the run buffer, After the run buffer in filled, put the soaked paper with sample at the sample paper slot. Then, the sample evaporates and it is dissolved in buffer. Then we can detect the sample by UV. The UV is provided by D2 lamp.